foam printer

A 3D printer for construction foam that can print furniture

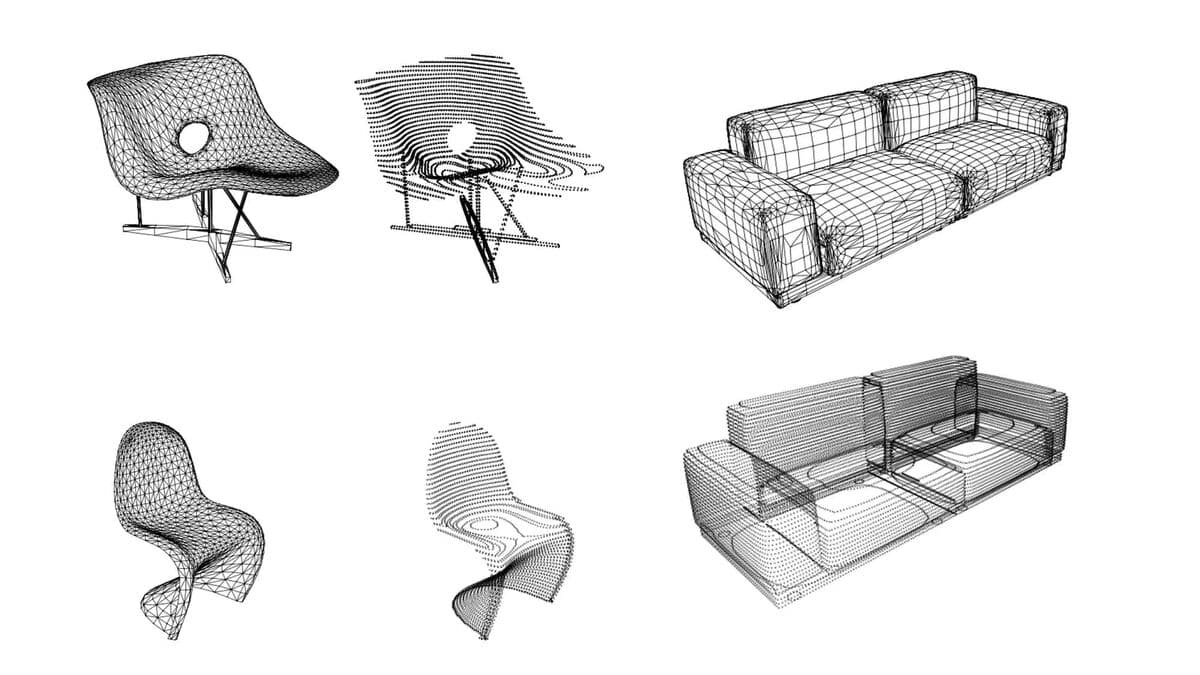

The briefing was to design chairs for a café. Since there are already plenty of great designs, we decided to not develop chair design #183192, but rather a way to replicate the designs that already exist with a new, experimental aesthetic.

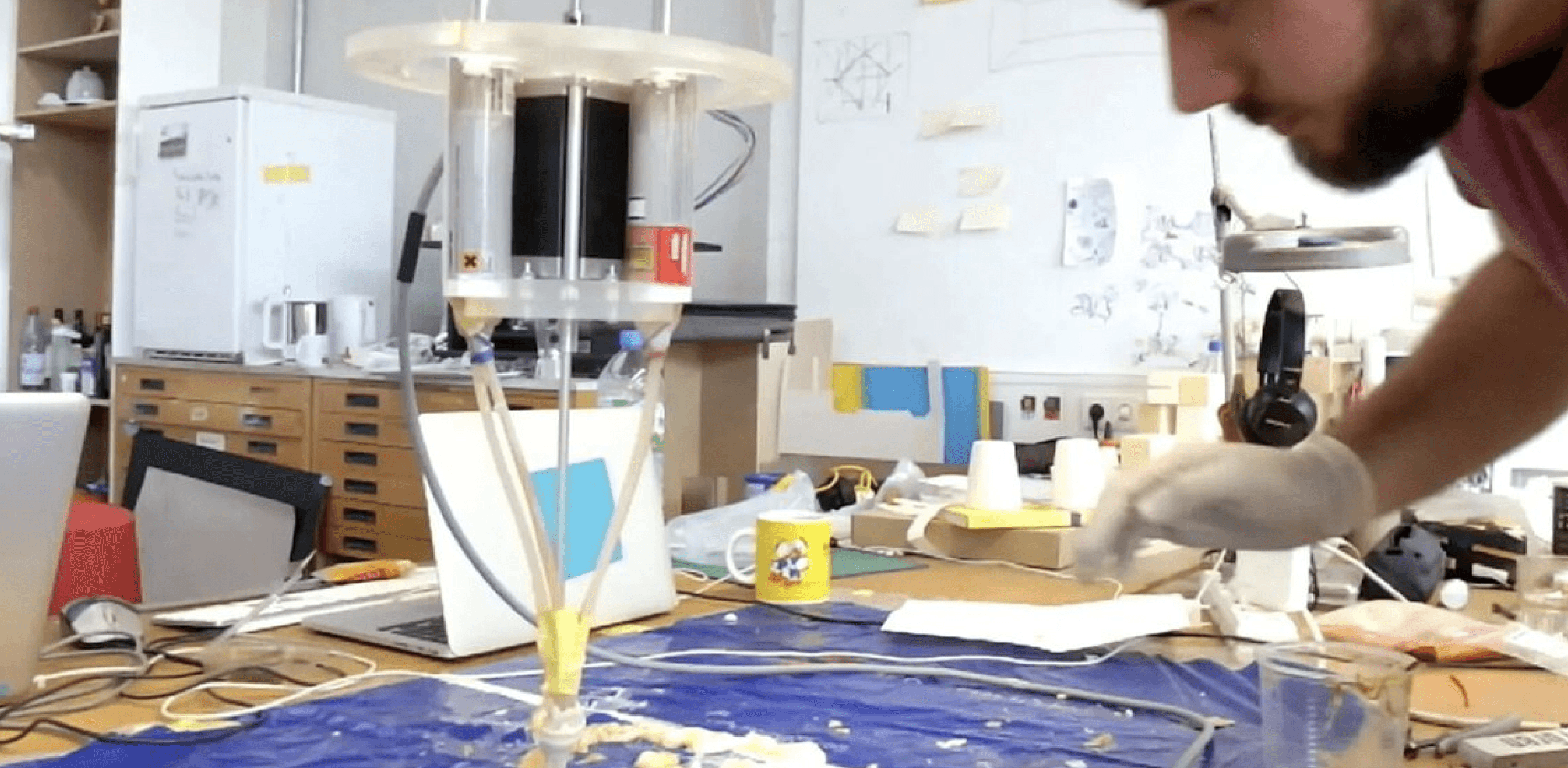

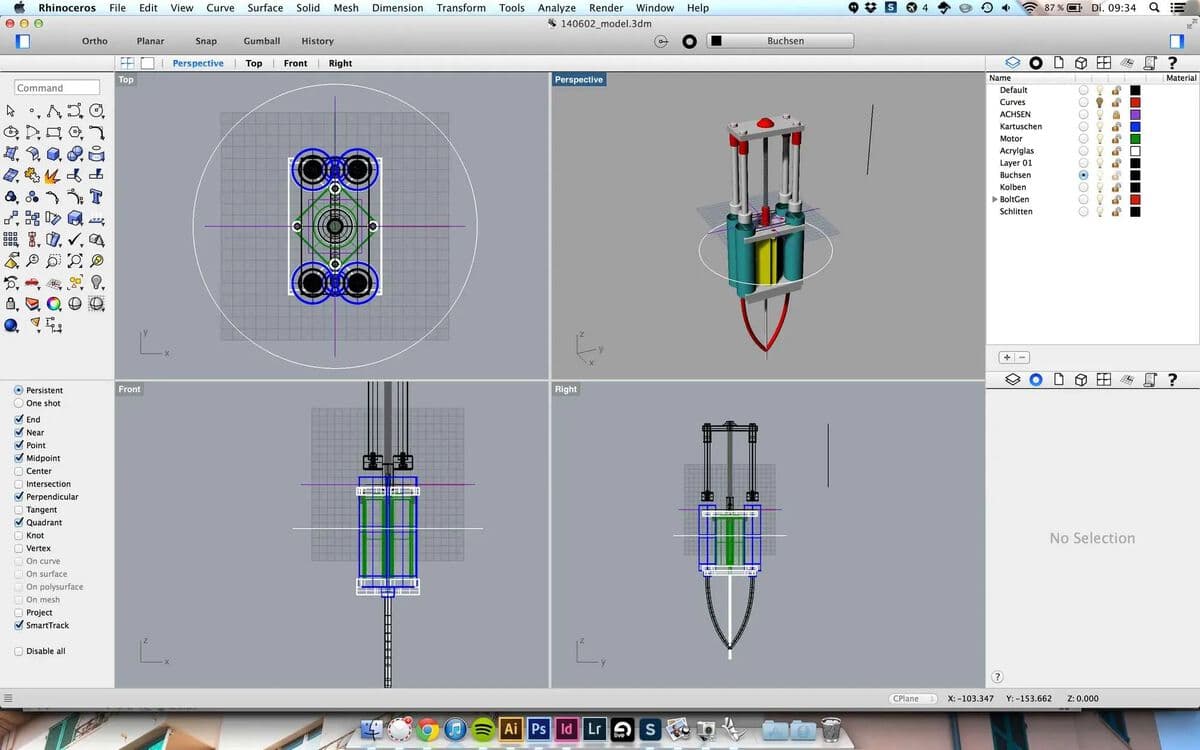

We developed a flying 3d-printer that would extrude foam usually used for construction. Since it was attached to the ceiling, there was no real limit to the size of objects.

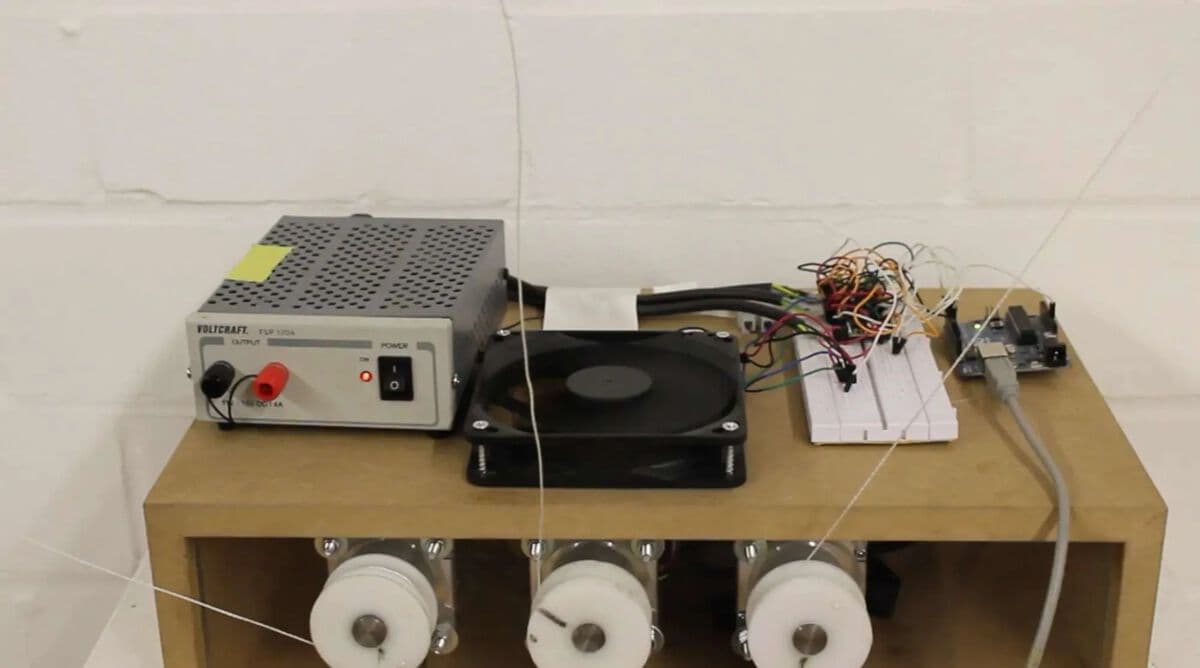

This was my first project using microcontrollers and motors so some things did not go as planned. The basis was an Arduino Uno running the CNC-Software GRBL and 3 NEMA17 stepper motors. These motors would act as winches controlling the length of thread thus controlling the position of the main unit in space.

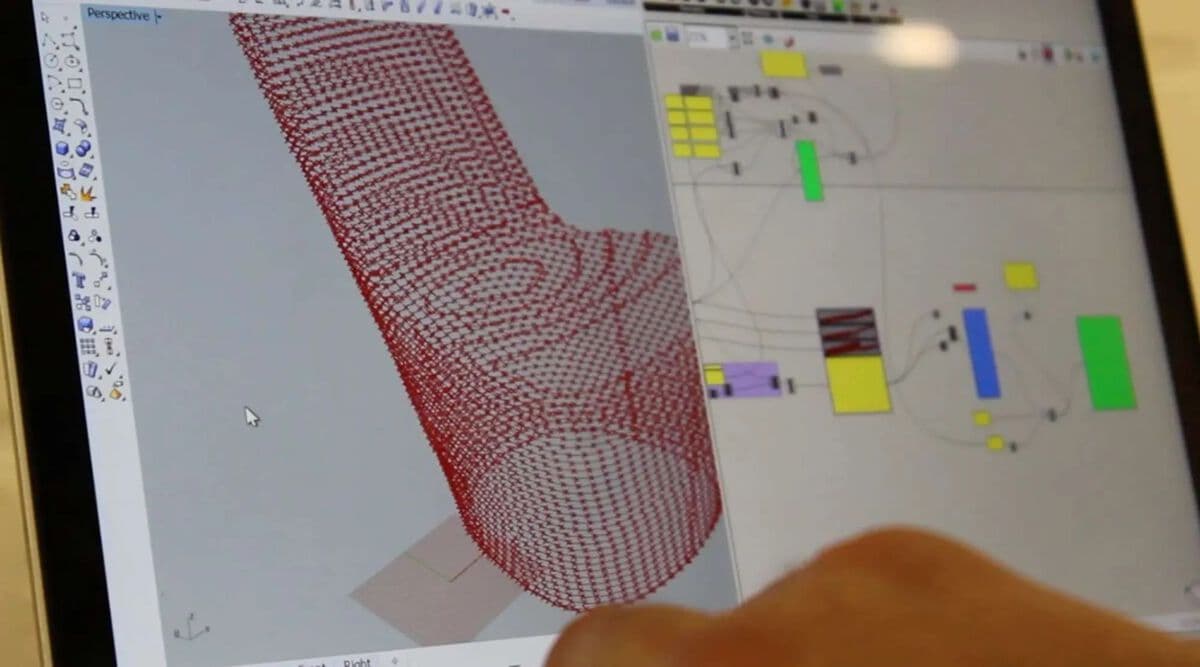

The NC-Code-generation was built entirely in grasshopper: slicing the geometry to positions, calculating the kinematics up to generating raw G-Code for the controller.

Unfortunately our skills at that time were not far enough to develop it into a fully functioning prototype. Also we had run out of time at some point.

We were however able to print a rather blocky chair at half scale, which worked as a proof-of-concept for us.

I would really love to start this project off again at some point, given that there are way more tools and software to work with – this was at a time when 3D-printing was yet to mature.

Project partners: Holger Mühlleitner